Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Implementation of Quality Management System for a Small Scale Building Construction project Sites.

Authors: Tejal Vishe, Dr. Yashvant Patil, Prof. Jyoti Aher B. A.

DOI Link: https://doi.org/10.22214/ijraset.2023.56583

Certificate: View Certificate

Abstract

The construction industry plays a crucial role in consistently delivering value and quality to its clients. Nevertheless, it faces challenges related to quality, leading to unsatisfactory outcomes, unsafe structures, and budget overruns. To address these issues, it is essential to establish a Quality Management System (QMS). This systematic approach ensures both product and process quality, not only satisfying customers and adhering to regulations but also reducing rework and waste. The successful implementation of a robust QMS involves tasks such as business analysis, initial planning, awareness raising, expert training, document control, deployment, measurement and control, auditing, and continuous improvement. This research focuses on the importance of quality management in small-scale construction projects during the execution phase. It involves data gathered from interviews and questionnaires with builders/contractors, consultants, and customers/building occupants. By examining the quality management practices of these small-scale building contractors and their impact on customer satisfaction, operational efficiency, and cost-effectiveness, this study aims to provide valuable insights into the matter.

Introduction

I. INTRODUCTION

In today's competitive market, it is imperative for construction companies to consistently deliver quality and real value to their clients. Establishing strong client relationships, fostering teamwork, and producing high-quality work are key objectives. Achieving these goals necessitates the implementation of a Continuous Improvement (CI) process, which forms the foundation of quality management. Quality is a critical factor in the success of construction projects, as it directly influences the satisfaction of all project participants. However, the construction industry in India has long grappled with quality issues, with a significant portion of the budget allocated to infrastructure projects. Contractors sometimes win contracts by submitting low-cost bids, compromising the quality of their work. Likewise, consultants may be pressured to cut initial construction costs, leading to subpar results. This absence of quality manifests in poor workmanship and unsafe structures, resulting in defective construction.

The appointment of consultants for limited construction services can increase risks and overall project costs, including disputes and delays. Long-term maintenance costs may also rise due to the lack of initial quality.

Quality management plays a crucial role in all stages of a construction project's life cycle. Quality is defined by how well a product or service meets customer expectations. Quality Management Systems (QMS) are designed to ensure consistent delivery of products or services that meet or exceed customer expectations.

The benefits of a robust Quality Management System are numerous. They include enhanced customer satisfaction, compliance with regulations, reduced rework and waste, data-driven decision-making, and an engaged workforce focused on continuous improvement.

Implementing a QMS impacts various departments and processes within an organization, promoting cross-functional communication and unity. To highlight the importance of quality management in the execution phase of construction projects, this research aims to shed light on the challenges and solutions in the construction industry. Developing and implementing a Quality Management System is a substantial undertaking that requires time and resources, but the potential benefits are substantial.

Quality-One offers customized support for organizations looking to develop and implement a robust Quality Management System, including consulting, training, and expert support. The concept of Total Quality Management (TQM) emphasizes the involvement of all organization members in creating and maintaining product and service quality. TQM aims to achieve quality by meeting customer needs, improving processes continuously, and involving everyone in quality management. Quality improvement techniques such as check-sheets, checklists, histograms, Pareto analysis, cause-and-effect diagrams, scatter diagrams, and flowcharts are essential tools for reducing variability and achieving quality.

In summary, the construction industry must prioritize quality to meet the evolving needs of clients and remain competitive. Implementing a Quality Management System and employing quality improvement techniques are crucial steps towards achieving excellence in construction projects.

II. LITERATURE REVIEW

Quality management systems play a crucial role in the field of construction, and this exploratory research investigates the practices, tools, techniques, and the essential commitment from management required for the successful implementation of quality in construction projects. Quality systems encompass both internal and external facets. Internally, the focus is on activities that instil confidence in an organization's management that the desired quality standards are being met, referred to as a "quality management system" (Abdul Aziz et al., 1999). A major hindrance to meeting quality improvement expectations is the absence of an effective quality planning process before implementation (Juran and Godfrey, 2000).

Despite various approaches such as Total Quality Management, Lean Construction, Supply Chain Management, Continuous Quality Improvement, Just in Time, and Total Quality Control, the construction industry still grapples with unsatisfactory quality performance and persistent issues (Miguel and Pontel, 2004; Tam and Le, 2008). To support these approaches, numerous techniques and tools have been employed, including the seven tools of quality (histograms, cause and effect diagrams, checklists, Pareto analysis, control charts, flowcharts, and scatter diagrams), Six Sigma programs (Parast, 2011; Tam et al., 2008), Cost of Quality (Abdelsalam and Gad, 2009; Tam and Le, 2007), and failure mode and effects analysis (Hawkins and Woollons, 1998; Yang and Peng, 2008).

The overarching goal of a Quality Management System is to proactively prevent errors. Recognizing that the knowledge of site staff is as vital as that of the management, there is a growing demand for quality cost training to enhance the skills and knowledge of site personnel (Samiaah M. Hassen Al-Tmeemy, Hamzah Abdul-Rahman, Zakaria Harun, 2012). The Quality Management System consists of three key phases: Quality Planning, Quality Control, and Quality Assurance (Pravin P. Mane, Dr. Jalindar R. Patil, 2015).

Research findings indicate that the implementation of a Quality Management System significantly affects customer satisfaction, cost, and time, with the lowest impact on scope (quality) in construction projects in Metro Manila (Behnam Neyestani, 2015). While there are numerous papers on the content of quality operation systems and suggestions for using quality instruments, there is no single methodological guide tailored to the unique characteristics of construction organizations (Sergey Lukichev, Marina Romanovich, 2016).

The implementation of Total Quality Management (TQM) within a firm has a substantial impact on the awareness level of its staff, aligning with the construction industry's shift towards promoting TQM in building projects (Yusr et al., 2017). The construction process is typically divided into three primary stages: the planning and design phase, the construction phase, and the maintenance and operation phase (Aawag Mohsen Alawag, Wesam, Salah Alaloul, M.S. Liew, 2022).

III. RESEARCH METHODOLOGY

When a common individual gazes upon a construction project, often through glossy brochures or promotional materials, they place their trust in the promised quality specifications. However, if the construction process harbour’s concealed quality defects, it constitutes a betrayal of trust by the contractors. The repercussions of such defects can extend to catastrophic building collapses, posing grave dangers. Therefore, it is imperative to take immediate measures to rectify quality maintenance failures in the construction industry. To address this challenge effectively, it is vital to thoroughly investigate the root causes and proactively adopt preventative measures to minimize such defects. The time has come for resolute decisions and their swift implementation to reduce the occurrence of quality maintenance issues. Comprehending the chosen methodology is of utmost importance, as it equips individuals with the skills to grasp its significance and aids in accurately interpreting research data. Research methodologies serve as the guiding tools for unravelling complex problems. A deep understanding of these methodologies provides the necessary training to apply them effectively in addressing real-world issues, allowing individuals to select appropriate techniques, materials, scientific instruments, and problem-solving strategies. In the context of establishing a Quality Management System for construction sites, the research methodology assumes a central role. It elucidates the foundational philosophical principles that underpin the selected research methods, whether they are qualitative, quantitative, or a fusion of both. Methodology encompasses a spectrum of research techniques, including literature review, publication research, interviews, surveys, and various other data collection methods. The focal point of this study is to delve into the existing Quality Management System, understand the factors impacting the quality of construction projects, and uncover the flaws within Quality Management during project execution. The study aims to devise practical strategies for rectifying these issues based on the data collected.

The research methodology comprises the following sequential steps:

- Commence with an extensive literature survey, encompassing a review of various journals and quality standards.

- Utilize the insights gained from the literature survey to pinpoint the factors exerting influence on quality management.

- Construct a questionnaire tailored to address these identified factors.

- Disseminate the prepared questionnaires to individuals sharing a similar background. Additionally, schedule personal interviews with contractors to delve deeper into the primary challenges they confront.

- Meticulously examine and interpret the collected data.

- Delve into the analysed factors and devise recommendations and solutions, with the objective of benefiting the contractors.

The questionnaire survey incorporates multiple optional points that necessitate rating on a five-point scale. The scale is defined as follows: "5= Extremely Strong, 4= Strong, 3= Moderate, 2= Less, and 1= Very less." It encompasses a combination of Yes/No questions and a handful of open-ended descriptive questions. In conclusion, a meticulously structured research methodology forms the bedrock of this study on Quality Management System for construction sites. It ensures that the research process is systematic, rigorous, and generates valuable insights into the challenges and opportunities within the construction industry. Ultimately, these insights contribute to improved quality management practices.

IV. DATA COLLECTION & ANALYSIS.

The primary objective of this research is to gain an in-depth understanding of quality management practices in the construction industry and to identify potential ways to enhance the quality of construction works. The design of the questionnaire is informed by a combination of insights derived from extensive literature reviews and the practical experience of field experts, including contractors, engineers, project managers, and consultants. These field experts possess valuable knowledge about the critical factors that significantly influence construction quality. The questionnaire places a specific focus on the execution phase, particularly the superstructure, recognizing that quality issues often arise during this crucial phase. More specifically, it concentrates on key elements such as column work, beam work, slab work, brick or block work, and plastering work. Although numerous factors can impact construction quality, this questionnaire specifically addresses major factors such as concreting work (covering aspects like concrete quality, pouring, compaction, and curing), workforce competence, material quality, equipment quality, and detailing. It employs a diverse range of question types, including Yes/No questions, scaled questions, and contingency questions. The use of a questionnaire in research is pivotal. It serves as a research instrument, comprising a series of questions and prompts, to collect valuable information from respondents. While questionnaires are often designed for statistical analysis of responses, some questionnaires incorporate scoring mechanisms, which enable the aggregation of answers to gauge the attitudes and opinions of respondents.

A. Questionnaire Sections

- Section A: Responders' Professional Data

In this section of the questionnaire, responders are requested to provide their professional information, allowing for the identification of their expertise and background.

2. Section B: Quality Management Techniques & Control Measures

a. The first question evaluates the use of various Quality Management techniques, offering a comprehensive overview of methods commonly applied in quality control within construction companies.

b. Question two inquiries x`about quality checks on construction materials, a critical factor for ensuring the quality of the final construction and adherence to industry standards.

c. The third question delves into the type of concrete used, providing insights into the sophistication of construction practices.

d. Question four focuses on skill training programs for site personnel, a vital component of maintaining quality and safety standards.

e. Questions five and six explore design processes, quality control, safety measures, and personnel training, all of which significantly impact the quality of construction projects.

f. Questions seven to ten assess the presence of safety measures, quality control guidelines, manuals, and training materials, all essential for ensuring quality and safety on construction sites.

g. Question eleven emphasizes the importance of material quality control in construction.

h. The twelfth question addresses the utilization of Personal Protective Equipment (PPE) to enhance the safety of site workers.

i. The thirteenth question explores various Quality Control measures adopted at construction sites, providing a comprehensive assessment of quality control practices.

3. Section C: Factors Affecting Quality on Building Construction Sites

This section is dedicated to identifying specific factors that exert an impact on the quality of construction projects. These questions are crucial for pinpointing areas that may require improvement and addressing potential quality issues.

4. Section D: Important Aspects for Maintaining Quality Management System

This section focuses on discerning the most crucial aspects for maintaining a Quality Management System at building construction sites. It aids in prioritizing elements that are indispensable for upholding quality in construction projects.

The questions and options within the questionnaire encompass a broad spectrum of factors and practices pertinent to quality management in construction. These thoughtfully designed questions aim to provide a comprehensive view of the existing practices and challenges within the construction industry without replicating specific sources.

Finally, the collected data will be utilized to rank Quality Control measures, Factors Affecting Quality, and Important Aspects based on their impact using the Impact Index. The Impact Index is calculated as the sum of the product of the frequency of the same score (low, medium, or high) divided by the total number of responses. This index assists in determining the factors that have the most significant impact on causing defects, with the factors ranked accordingly. Impact Index (I.I) is calculated as follows:

Impact Index = (∑F r x r/N)

Where: -

- r = severity score (Low=1, Medium=2, High=3)

- F = frequency of factors receiving a score of r

- N = total number of respondents

V. DISCUSSIONS & FINDINGS

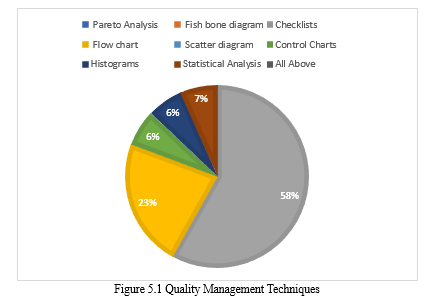

A. Quality Management Techniques

The questionnaire survey yielded valuable insights into the quality management techniques employed in the construction industry. According to the responses, the most important quality management technique used at construction sites is the use of Check Lists. This is followed by the utilization of Flow Charts, Statistical Analysis, Control Charts, and Histograms, all of which play a significant role in ensuring quality within construction projects.

C. Importance of Design Process and Training

The study also emphasized the importance of the design process in ensuring safety, efficiency, and effectiveness in formwork. The design process encompasses various critical considerations, including structural elements, material selection, construction sequence planning, safety measures, compliance with industry codes and standards, and cost optimization. This systematic approach to design is vital in achieving quality and safety in construction. In terms of training programs, a substantial 80.5% of respondents conduct skill training programs for site engineers, supervisors, and masons. ISO 9001 registered companies exhibit a higher commitment to employee training, providing courses during working hours, further emphasizing the importance of training in quality management. Training, a fundamental element of Total Quality Management (TQM), ensures that employees fully understand their roles and responsibilities, fostering a culture of continuous improvement and increased job satisfaction.

D. Safety Measures and Quality Control Guidelines

The survey indicated that safety measures and quality control guidelines are widely adopted in the construction industry. A significant 93% of respondents reported providing periodic instructions to drivers, contributing to a culture of safety and compliance. Additionally, 95.3% of respondents noted the existence of quality guidelines and safety manuals within their companies, reinforcing the commitment to safety and quality within construction projects.

E. Personal Protective Equipment (PPE) Usage

Usage of Personal Protective Equipment (PPE) is prevalent in the construction industry, with 75% of respondents reporting its regular use. An additional 20.5% use PPE sparingly, underlining its role in safeguarding workers from potential hazards. Ensuring the proper use of PPE is essential for the safety and well-being of construction personnel.

Quality Control Measures The survey highlighted the significance of quality control measures implemented at construction sites to ensure the quality of materials and workmanship. Key measures include rigorous testing and sampling, adherence to prescribed curing and de-shuttering schedules, maintaining the sequence of construction, defining responsibilities and duties, conducting regular inspections, and holding site review meetings. These practices contribute to quality assurance in construction projects.

Table 5.1 Quality Control Measures

|

Sr. No. |

Quality Control measures |

Impact Index |

|

1 |

Quality of material in all construction activities. |

2.58 |

|

2 |

Study responsibilities & duties. |

2.48 |

|

3 |

Set procedures to control quality. |

2.50 |

|

4 |

Quality of workmanship in all construction activities |

2.48 |

|

5 |

Site review meetings with staff |

2.48 |

|

6 |

Follow the prescribed curing and DE shuttering schedules. |

2.46 |

|

7 |

Maintain sequence of construction |

2.52 |

|

8 |

Do proper testing and sampling. |

2.54 |

|

9 |

Inspections on regular or weekly basis. |

2.46 |

F. Factors Affecting Quality in Construction

The survey identified several factors that can significantly impact the quality of construction projects. These factors include slight changes in column marking, poor designing, improper shuttering work, inadequate manpower on-site, equipment quality, compaction of concrete, improper curing of columns, changes in plastering thickness, quality of concrete used, inadequate drawing studies, the starter course in block work, and wetting of bricks or blocks before laying.

Table 5.2 Factors Affecting Quality

|

Sr. No. |

Questions for factors affecting Quality on site |

Impact Index |

|

1 |

Does slight changes in column marking affects the quality? |

2.08 |

|

2 |

How Severely does poor designing effects on quality? |

2.52 |

|

3 |

Does issue arise due to improper shuttering work? |

2.44 |

|

4 |

Does less manpower on site affect the quality of construction? |

2.13 |

|

5 |

Will the equipment’s used on-site cause problems? |

2.29 |

|

6 |

Compaction of concrete to a lesser extent than required affects quality? |

2.38 |

|

7 |

Does any quality issue arise due to improper curing of column? |

2.46 |

|

8 |

Will a Change in plastering thickness affects the quality? |

1.98 |

|

9 |

Is the quality of concrete influencing the quality of slab and beam? |

2.56 |

|

10 |

Does improper drawing study cause any kind of quality problem due to? |

2.44 |

|

11 |

Does the starter course lie affect the quality of block work? |

2.44 |

|

12 |

Does not wetting the brick or block before lying cause problems? |

2.50 |

G. Important Aspects for Maintaining Quality Management System (QMS)

The importance of a Quality Management System in construction projects is evident, with customer satisfaction being the highest priority according to 93% of respondents. Management commitment, stakeholder satisfaction, client satisfaction, and competitive markets also ranked highly. This emphasizes the multifaceted role of a QMS in construction, encompassing the satisfaction of various stakeholders and ensuring competitive success in the market.

Table 5.3 Important Aspects for Maintaining QMS

|

Sr. No. |

Important aspects for maintaining QMS |

Impact Index |

|

1 |

Customer satisfaction |

2.51 |

|

2 |

Management commitment |

2.33 |

|

3 |

Stakeholders’ satisfaction |

2.40 |

|

4 |

Client satisfaction |

2.42 |

|

5 |

Competitive markets |

2.48 |

The findings from the questionnaire survey provide valuable insights into the current practices and challenges within the construction industry, highlighting the importance of quality management techniques, material quality, design processes, training, safety measures, and adherence to quality control measures. The factors affecting quality in construction underscore the need for precise execution in various construction activities. Moreover, the prioritization of customer satisfaction and management commitment affirms the critical role of a Quality Management System in construction projects. These findings lay the foundation for future improvements and advancements in quality management within the construction industry.

Conclusion

In conclusion, this research has revealed several key findings and implications: 1) Quality Management Systems are pivotal for achieving consistency in meeting customer needs and optimizing project performance through a process-oriented approach. 2) The design process for formwork in construction projects plays a critical role in ensuring safety, efficiency, and effectiveness, involving structural considerations, material selection, and compliance with standards. 3) Quality control measures and safety protocols are essential for verifying compliance with standards and safeguarding workers on construction sites. 4) Skill training programs, especially in ISO 9001 registered companies, contribute to employee development and enhanced job satisfaction. 5) Various factors, such as changes in column marking, poor designing, improper shuttering work, manpower issues, equipment quality, compaction of concrete, curing practices, plastering thickness, and concrete quality, can significantly affect the quality of construction. 6) A robust Quality Management System is vital for customer satisfaction, competitive market positioning, and stakeholder commitment in construction projects. In summary, the research underscores the importance of a systematic design process, quality control measures, skill training, addressing quality-affecting factors, and a strong Quality Management System in achieving high-quality construction projects.

References

[1] Aawag Mohsen Alawag, Wesam Salah Alaloul (2021): “Total quality management in industrialised building system: Implementation and benefits in construction projects”, Ain Shams Engineering Journal, 14 (2), 101877. [2] Ahmad Rashed, Mohammad Othman (2015); “Implementing Quality Management in Construction Projects”, Dubai, United Arab Emirates (UAE), 3 (5), 2329- 2334. [3] Ahmet Özta?, Serra S Güzelsoy, Mehmet Tekinku? (2007), “Development of quality matrix to measure the effectiveness of quality management systems in Turkish construction industry”, Building and Environment 42 (3), 1219-1228, [4] Albert P.C. Chan, C.M. Tam, (2000), \"Factors affecting the quality of building projects in Hong Kong\", International Journal of Quality & Reliability Management, 17(4/5), 423-442. [5] Almarzooqi, S., Alkamali, W., El Khatib, M., Talib, M., & Alteneiji, R. (2023), “Project Quality and Project Risk Management: Correlations and Interdependencies”. International Journal of Business Analytics and Security (IJBAS), 3(1), 139–156. [6] AnupW S1, Arun Kumar H2, SNA Saqhi (2015), “Study of Quality Management System in Construction”, (IRJET), 2 (2), 462-467. [7] Azlan S. Ali, Ismail Rahmat (2010), “The performance measurement of construction projects managed by ISO-certified contractors in Malaysia”, Journal of Retail & Leisure Property, 9, 25 – 35. [8] David Arditi, Dong-Eun Lee (2003), “Assessing the corporate service quality performance of design-build contractors using quality function deployment”, Construction Management & Economics 21 (2), 175-185. [9] Douglas D Gransberg, Keith Molenaar (2004), “Analysis of owner’s design and construction quality management approaches in design/build projects”, Journal of management in engineering 20 (4), 162-169. [10] David Arditi and H Murat Gunaydin, (1997), “Total quality management in the construction process”, International Journal of Project Management, Elsevier Science Ltd and IPMA, 15 (4), 235-243. [11] Ekambaram Palaneeswaran, Thomas Ng, Mohan Kumaraswamy (2006): “Client satisfaction and quality management systems in contractor organizations”, Building and environment, 41 (11), 1557-1570. [12] Hesham Abdel Khalek, Remon F. Aziz, Esraa A. Sharabash (2016), “Applications and Assessment of Quality Management in Construction Projects”, International Journal of Innovative Research in Engineering & Management (IJIREM); ISSN: 2350-0557, 3 (5). [13] Hoonakker, Peter, Carayon, Pascale and Loushine, Todd (2010), “Barriers and benefits of quality management in the construction industry: An empirical study”, Total Quality Management & Business Excellence, 21: 9,953-969. [14] Idris Othman, Siti Norfarahhanim Mohd Ghani, Shim Woon Choon (2020), “The Total Quality Management (TQM) journey of Malaysian building contractors”, Ain Shams Engineering Journal, 11, 697–704. [15] Ivanov Nikolay (2016), “A study on optimization of nonconformities management cost in the quality management system (QMS) of small-sized enterprise of the construction industry”, Elsevier Science Ltd, 153, 228 – 231. [16] James L. Burati Jr.,Member, ASCE, Michael F. Matthews, and Satyanarayana N. Kalidindi (1992), “Quality Management Organizations And Techniques”, Journal of Construction Engineering and Management, 118(1), 112-128. [17] Junying Loua, Jiang Xu, Kun Wangc (2017), “Study on Construction Quality Control of Urban Complex Project Based on BIM.”, Elsevier Ltd. [18] Kardule Snehal Ashok, Khandre Rajshree (2022), “Review on Total Quality Management: A Quality and Innovative Performance”, International Journal of Research Publication and Reviews, 3 (7), 296-304. [19] Longenecker, C.O. and Scazzero, J.A. (1993), \"Total Quality Management from Theory to Practice: A Case Study\", International Journal of Quality & Reliability Management, 10 ( 5 ).

Copyright

Copyright © 2023 Tejal Vishe, Dr. Yashvant Patil, Prof. Jyoti Aher B. A.. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56583

Publish Date : 2023-11-08

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online